Hanks are seized to the foresails when we want them to be able to slide up and down on a stay as we hoist or lower them. In the earlier days as the stays and shrouds were made of hemp rope the hanks were wooden. As the vessels were rigged with wire rope the hanks were forged.

The hanks clammer the foresails to the stays. Here Brødrene af Sand are in the wind.

The hanks clammer the foresails to the stays. Here Brødrene af Sand are in the wind.

As we worked on the polar expedition ship Fram earlier this year our blacksmith had to make quite a few hanks. Here is from the prosess in the smithy.

After shaping a square rod into a oval shaped rod Seppe shapes the ends of the rod to a dull point.

After shaping a square rod into a oval shaped rod Seppe shapes the ends of the rod to a dull point.

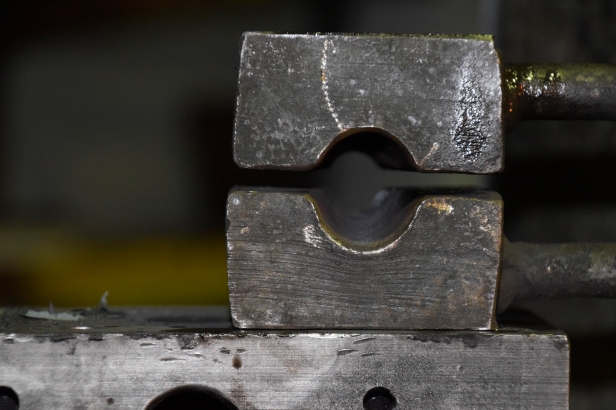

In a mold the end is nicely shaped to a cone.

In a mold the end is nicely shaped to a cone.

The cone shaped form that makes the “curls” look nice.

The cone shaped form that makes the “curls” look nice.

And here we go. Bend the end to a nice curl.

And here we go. Bend the end to a nice curl. Looking good.

Looking good.

Checking the diameter

Checking the diameter

Then the shape of the hank itself is made. Half at a time.

Then the shape of the hank itself is made. Half at a time.

Then the other side.

Then the other side.

Forced nicely towards the pipe to get the right shape. The shape might differ from one style to another.

Forced nicely towards the pipe to get the right shape. The shape might differ from one style to another.

The foresail of Fram is set with the blacksmiths new hanks.

The foresail of Fram is set with the blacksmiths new hanks.

Drawing Sarah Sjøgreen

Drawing Sarah Sjøgreen

The way the hank is seized to the luff of the sail. The stay is not shown on this drawing.

A nontraditional kind of hank on board this vessel, but it shows very well the purpose.

A nontraditional kind of hank on board this vessel, but it shows very well the purpose.